Steel Normalizing Heat Treatment Services in Plymouth, MI

Open Material Opportunities with Normalizing Heat Treatment

Open Material Opportunities with Normalizing Heat Treatment

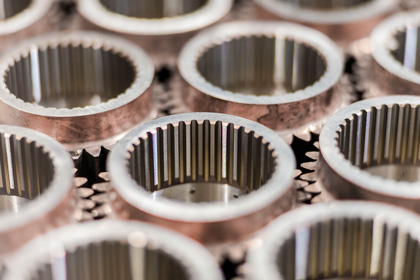

RMT offers many heat treatment options, including steel normalizing for metal pieces and parts. This process includes a high-temperature heating cycle followed by air cooling. Microscopic segregation or non-uniformities become a thing of the past with normalizing. Though there is overlap with the processes of annealing, hardening, and stress-relieving, the main goals of normalizing are to gain homogenized grain structure, enhance machinability, reduce added stress, and improve how the piece responds to any future heat treatment.

Depending on what was previously done to a piece of metal, normalization has the potential to increase or decrease the hardness and strength of a product. Homogenization is necessary for castings to break up or refine their structure at the time of casting to improve the impact of subsequent hardening processes. The reduction in grain size helps bring uniformity to pieces with mixed large and small grain sizes.

More Opportunities with Cooling and Normalizing with the RMT Experts

More Opportunities with Cooling and Normalizing with the RMT Experts

There are necessary situations to use normalizing, such as when noticeable differences exist in the grain levels of pieces. However, sometimes the size or shape of a part will cause it to crack, distort, or alter too much during the liquid quenching portion of traditional hardening. The more complicated the shape of a unit is, the more likely the process of normalizing and tempering will be a viable option.

For over 50 years, RMT Woodworth Heat Treating has been a family-owned business providing metal heat treating services. We reduce distortion of metal pieces by offering rack and fixture processing. We individualize our service by delivering specialized treatment and customization options that still live up to our high-quality standards. RMT’s certifications in IATF, CQI-9, and NSF support industry and public health standards.